Share with:

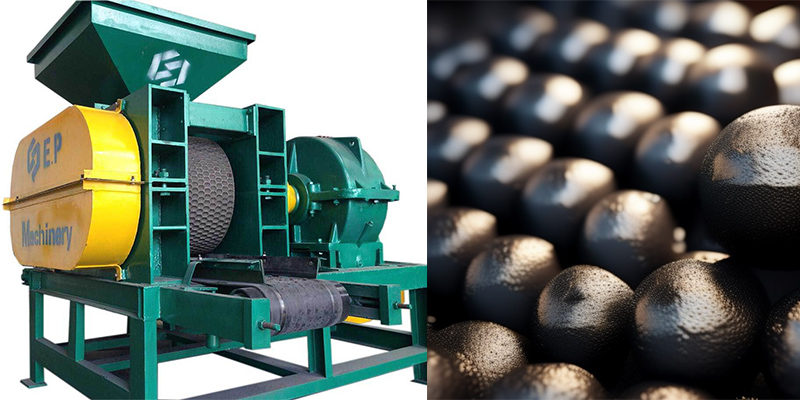

In industrial production, how to efficiently and conveniently compress pulverized coal into lump fuel has always been a problem faced by many companies. Today, the briquette briquetting machine we are going to introduce to you is the ideal choice to solve this problem. This briquette briquetting machine uses an electric motor as its power source, and through precise design and excellent craftsmanship, it can achieve fast and efficient suppression of pulverized coal.

Let’s take a look at the transmission system of the briquette briquetting machine. The machine uses a high-performance electric motor as power, which is transmitted to the drive shaft through pulleys and couplings, ensuring the stability and reliability of the power. At the same time, the driven shaft and the driving shaft rotate in opposite directions through gears, maintaining synchronization. This design ensures smooth movement of the rollers, resulting in smoother briquette production.

When the coal material is fed into the machine and falls between the two counter-rotating rollers, strong pressure begins to act on each pulverized coal particle. These carefully designed rollers not only have high strength, but also have a smooth and durable surface, capable of pressing pulverized coal into uniform spherical shapes under high pressure. During this process, each hole position is accurately matched to ensure that every pressing can produce high-quality briquettes.

What's more worth mentioning is that this design also takes pressure changes into account. When the holes on the two rollers are aligned with each other, the pressure reaches a peak to ensure that the pulverized coal is compacted; when the holes are staggered, the pressure gradually decreases to zero, and the formed briquettes will automatically fall off, completing a production cycle. . This cycle not only improves production efficiency, but also reduces energy consumption.

Using the briquette briquetting machine, you will find that both operation and maintenance are extremely convenient. Its user-friendly design makes it easy for operators to get started, while its sturdy structure ensures long-term stable operation. In addition, cleaning and maintenance of the machine are also very simple, without too many tedious steps.

Faced with such an efficient, energy-saving and easy-to-operate briquette briquetting machine, have you already seen its application scenarios in your factory? If you are looking for a solution to improve pulverized coal processing efficiency and reduce production costs, this briquette briquetting machine is undoubtedly a wise choice. Don’t hesitate anymore, act now, introduce this innovative equipment to your company, and start a new era of energy saving, emission reduction, and efficient production!

CONTACT US